做过塑胶模具抛光处理的生产厂家都了解,着急是吃不上西施豆腐的,做模具抛光处理避讳的就是说急功近利。1个技术好的模具抛光处理厂家,了解抛光是1个由浅入深的工艺流程,今天,济南注塑模具加工厂给大家讲解一下模具镜面抛光的方式代表什么!

Manufacturers who have done plastic mold polishing know that they can't eat Xishi tofu in a hurry. The taboo to do mold polishing is to be eager for quick success and instant benefit. A mold polishing manufacturer with good technology understands that polishing is a process from shallow to deep. Today, Jinan injection mold processing factory will explain to you what the way of mold mirror polishing represents!

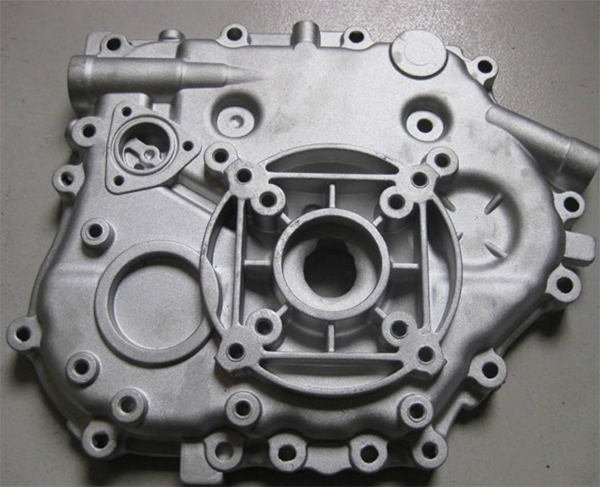

济南注塑模具加工厂

Jinan injection mold processing factory

抛光必须循序渐进,循规蹈矩的来开展工作中,首要须要应用由粗到细的油石,开展相对的加工,待上一步作完以后,再从粗砂纸一步一个脚印过到细的砂纸,随后就必须应用不一样型号规格的钻石烟磨膏做好由粗到细的抛光。

Polishing must be carried out step by step. In the work, it is first necessary to apply the coarse to fine oilstone to carry out relative processing. After the previous step is completed, it will go step by step from coarse sandpaper to fine sandpaper, and then diamond smoke grinding paste of different models and specifications must be used to polish from coarse to fine.

镜面抛光一起还涉及专用工具的运用,粗加工的那时候,抛光技术工作人员针对油石的使用方法也有强度全是有相对的技术要求得,移动得部位要均匀,不容易擦起沟痕,砂纸是需要应用高质量得,而且针对研磨的木板都是分软木都有硬木,粗研磨一般全是选用硬木,而抛光则就相对需要使用软木,再配合进口的钻石研磨抛光膏才可以达到镜面的效果。

Mirror polishing also involves the use of special tools. At the time of rough machining, the polishing technical staff also had relative technical requirements for the strength of the use method of oilstone. The moving parts should be uniform and it is not easy to wipe groove marks. Sandpaper needs to be of high quality. Moreover, the polished wood is divided into cork and hardwood, Generally, hardwood is used for rough grinding, while cork needs to be used for polishing, and then combined with imported diamond grinding and polishing paste to achieve the effect of mirror.

镜面抛光针对模具镜面抛光的自然环境都是拥有很高的规定,许多高精尖的产品需要达到十分级的标准,才能够进行模具镜面抛光。

Mirror polishing has high regulations for the natural environment of mold mirror polishing. Many high-precision products need to reach the tenth level standard before mold mirror polishing can be carried out.